The task - fully demineralised water for the electroplating process

If you want to master the production of high-quality dials and watch components, you have to look above, below and next to the dial. This also applies to electroplating processes, which require demineralised water (demineralised water), also known as demineralised or deionised water.

The quality of the water used must meet strict standards of purity and conductivity to ensure a uniform and flawless coating. This is because the quality requirements of watch manufacturers in terms of precision and perfection are subject to the highest criteria.

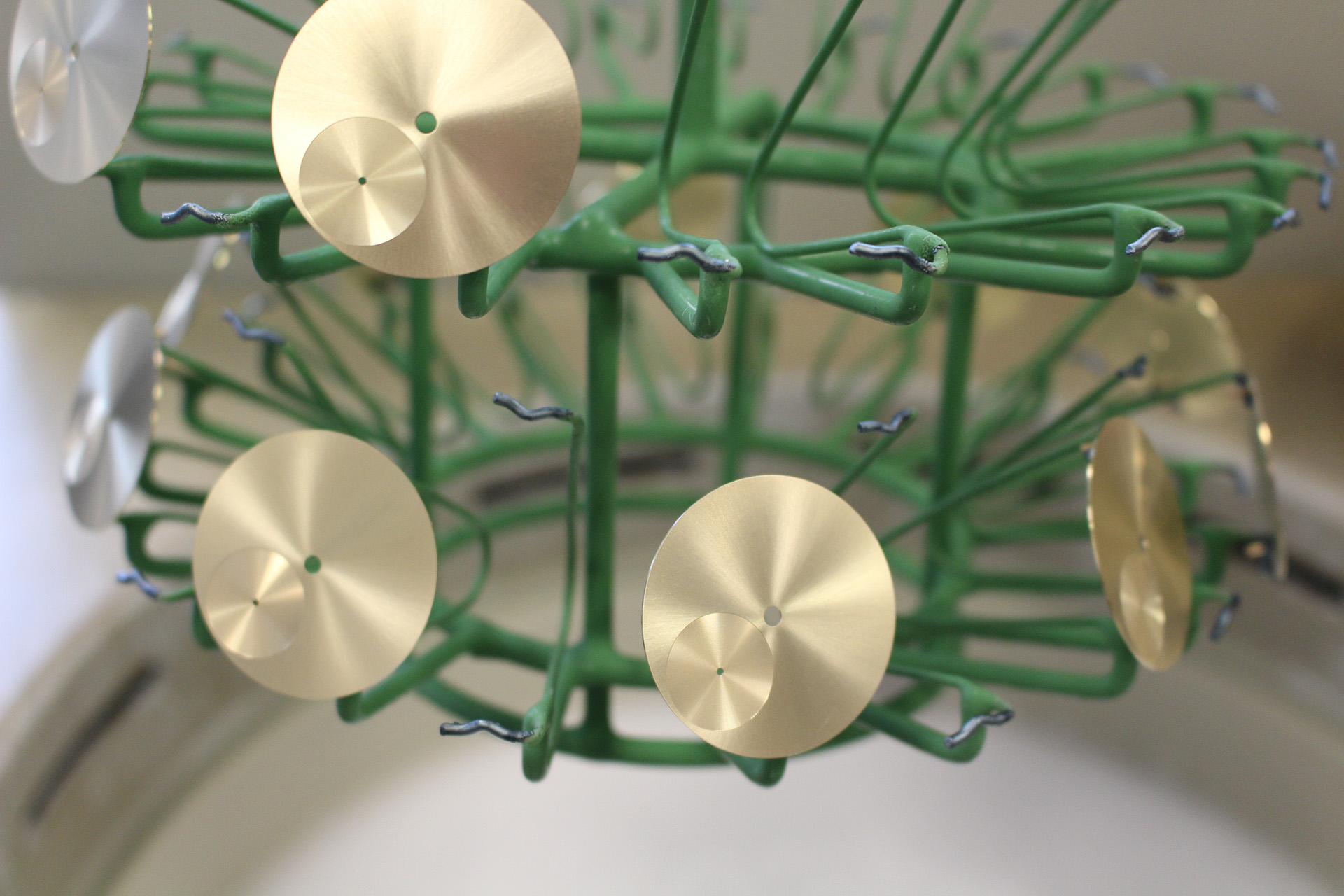

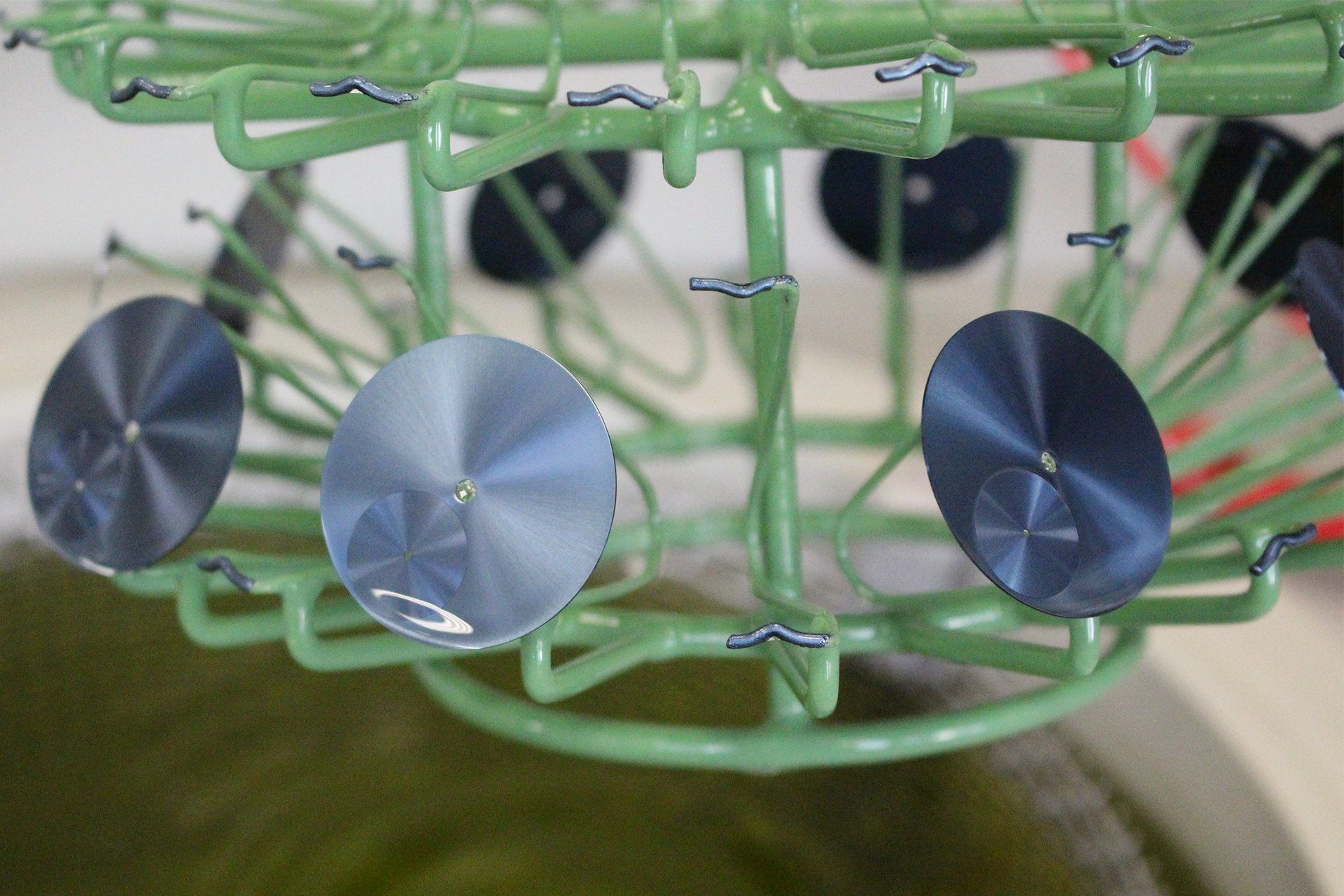

CADOR GmbH has specialised in the manufacture of fascinating dials for wristwatches, pocket watches, on-board clocks, dial gauges and precision milled parts for over 65 years. From in-house toolmaking to precision assembly, all specialist areas are united under one roof in Eimeldingen – in the border triangle of Germany, Switzerland and France.

The wide range of surface treatments such as polishing, various blasting and effects, combined with the electroplating baths, result in an almost inexhaustible variety of options for the production of dials and movement components. The electroplating processes used to refine and protect the dials and high-quality watch components contribute significantly to the quality and durability of the watches.

The solution - EnviroFALK selective ion exchangers for electroplating baths

The experts at EnviroFALK have specialised in the different requirements of industrial water treatment and water treatment. This also applies to companies in the watch industry and watch component manufacturers. From compact water treatment systems for standard applications to customised plant construction and a comprehensive range of services, EnviroFALK develops perfectly coordinated solution concep

Selective ion exchangers can be used to remove dissolved heavy metals from galvanic rinsing water. And to such an extent that the limit values for discharge into the public sewage system are easily met.

However, the special selective exchange resin inside the cartridge systems is exhausted after a certain loading time and requires professional treatment. The experts at EnviroFALK have been offering a regeneration service for selective exchangers for more than 35 years. State-of-the-art technology and in-house water circuits in the EnviroFALK regeneration station for ion exchange resins ensure a resource-saving operating process. In addition, the regenerates and rinsing water produced are also treated in the special waste water treatment plant.

The advantages of EnviroFALK selective ion exchangers

Mobile selective ion exchangers are particularly interesting when small quantities of wastewater, low load quantities and widely varying wastewater quantities are produced. EnviroFALK also has a licence that allows it to collect and transport selective ion exchangers loaded with heavy metals. The service does not just include ion exchanger regeneration. EnviroFALK collects the exhausted selective ion exchangers on site and brings them back to be reconditioned.

Conclusion

Andreas Reisch

Managing Director at CADOR