Interesting facts about ion exchanger regeneration

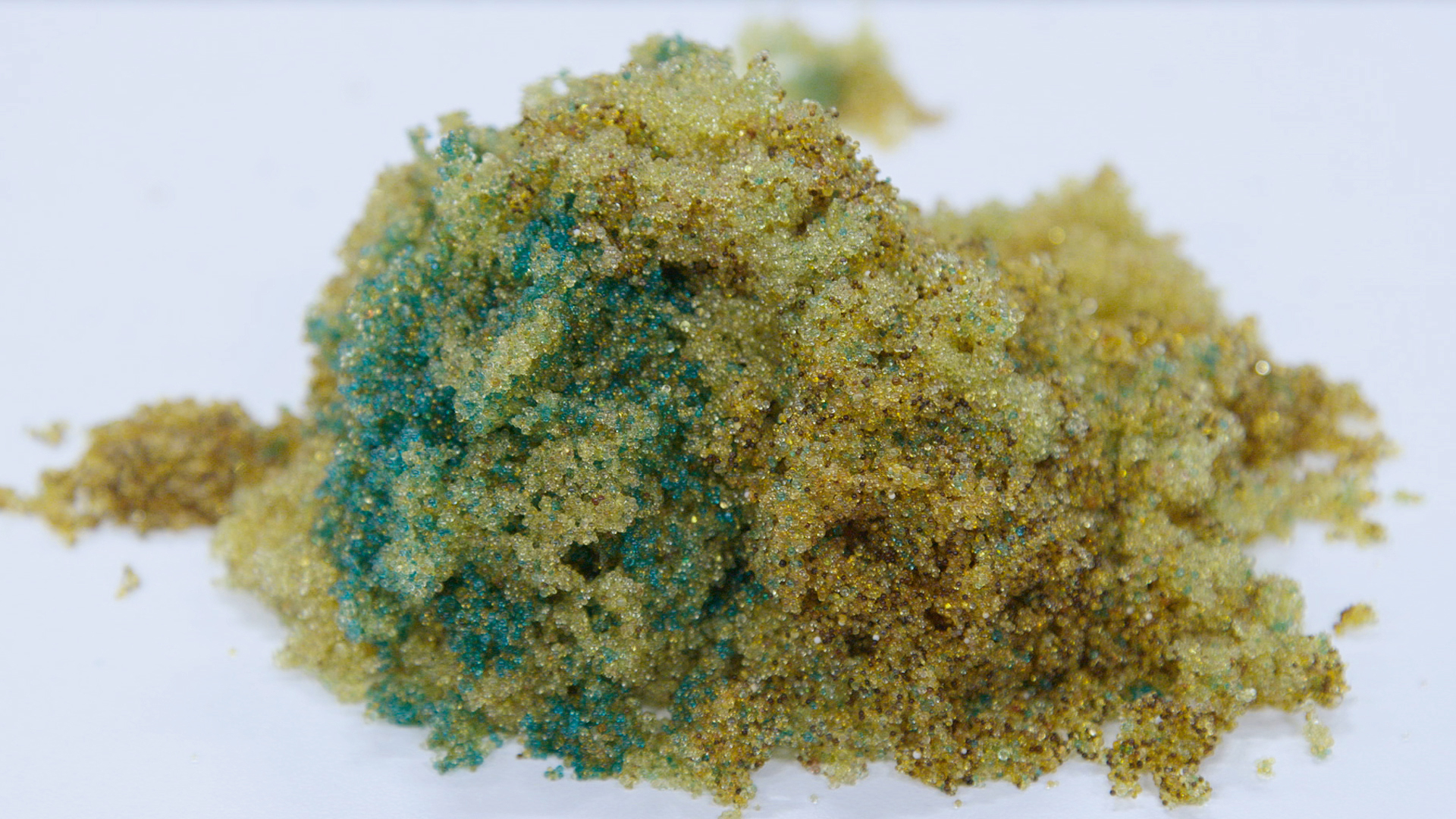

When we talk about ion exchangers, we mean the resin inside the ion exchanger cartridge, which is often referred to as the resin bed. This special resin is used to exchange unwanted ions from a solution for ions of the same charge – hence the name “exchanger”. The ions from the water virtually swap places with the ions on the resin bed.

Where should we start? High-quality ion exchangers have become indispensable in so many different areas – from industry and commerce to laboratories and medical technology. The best thing to do is to take a look around our website. Find out for which industries ion exchangers are indispensable. And if you notice that your industry is not listed on our website: Please let us know! As an all-rounder with high quality standards, we still find the right solution for every need.

The resins in the ion exchanger are exhausted at some point. As a result, no more ions can be absorbed from the water, which of course stands in the way of producing fully demineralized water – also known as demineralized water. However, a special regeneration process can restore the efficiency and performance of the resins. There is no general answer as to how often regeneration should take place, as various factors play a role here, including the type of ion exchanger, the concentration of ions contained in the water and the consumption of the water.

As described above, the ions in the solution to be treated swap places with the ions on the resin. At some point, however, there is no more room on the ion exchanger resin. As part of a regeneration, free spaces have to be created again, so to speak. This process can be simplified as follows:

First, the resin bed is backwashed to remove and loosen up suspended particles. A special regeneration agent is then used to displace the foreign ions that have been absorbed and exchanged by the ion exchange resin and replace them with regeneration ions (H⁺- or OH- ions). Finally, the ion exchanger bed is washed at regular operating speed until the desired water quality has been achieved.

There are several ways to treat ion exchangers. A rough distinction is made between two variants: co-current and counter-current regeneration. In practice, the counter-current process has become established as, unlike the co-current process, it actually enables complete regeneration of the ion exchangers. The regenerating agent does not have to pass through the entire resin bed first and thus also displace it. First, the layers that are least polluted are loaded with new ions. The layers that are heavily loaded then receive the full dose of the regenerating agent. This is not possible with the direct current method.

We will be happy to answer your questions. Modern water treatment using ion exchangers is one of our favorite topics that we can talk about for hours. So if you would like to find out more or contact us directly: You will find our contact details on the left of this page – we look forward to your message or call.